VINNOVA programme “Effective Product Development”

2002-2005 (finalized)

PROJECT SUMMARY

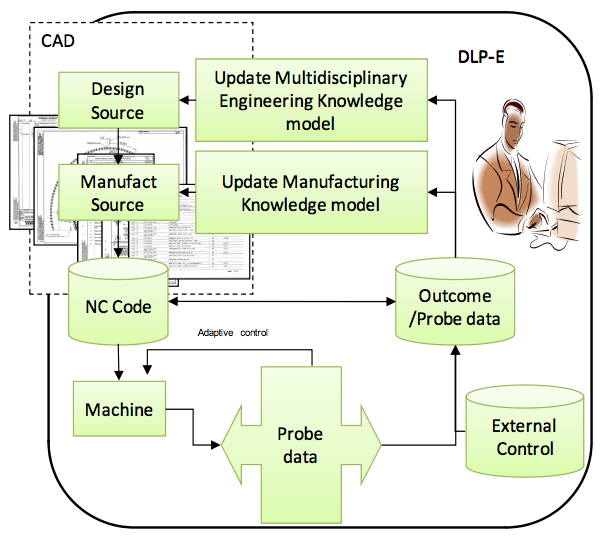

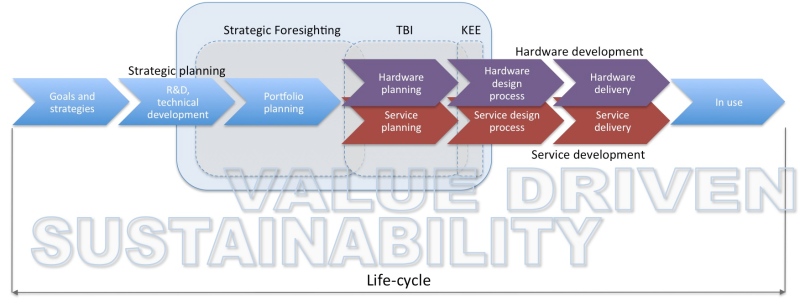

The conceptual design phase is the perhaps most important phase, determining most functions and cost of the forthcoming product. Knowing that the concepts to a large extend also sets the manufacturing conditions; it is critical to take manufacturing process information into account in earliest possible stages.

This project aims at providing the engineering platform for conceptual design, enabling the manufacturing properties to be properly evaluated early on. This engineering platform is the natural environment where specific engineering methods can be integrated. Main focus is to represent the manufacturing process to a level where product and life cycle cost properties can be made available to the conceptual design team.

The scope of the research is to enable the evaluation of manufacturing process information in conceptual design by means of Knowledge Based Engineering (KBE) and Engineering Design methods.

PROJECT INFORMATION

Role: Project leader, main applicant, phd candidate supervisor

Type: Research

Keywords: Product/Service Systems, Functional Product Development, Knowledge Enabled Engineering, Knowledge Based Engineering, Product Development

Application area: Aeronautics and Space, Automotive

Time frame: 20020801-20050801

Funding: 6 MSEK

Research unit: Luleå University of Technology

Partners: VINNOVA, Volvo Aero AB, SAAB Automobile, Q-Company (Norway)

PUBLICATIONS

- A design tool integrating CAD and virtual manufacturing for distortion assessment

- Automating redesign of sheet-metal parts in automotive industry using KBE and CBR

- Combining knowledge-based engineering and case-based reasoning for design and manufacturing iteration

- Functional product life-cycle simulation model for cost estimation in conceptual design of jet engine components

- Knowledge enabled engineering design tools for manufacturability evaluation of jet engine components